Breathing easier: Aurovilians building ventilators

FeatureBy Peter

Keywords: COVID-19 pandemic, JASAN ventilator, JASAN team, Tusky ventilator, Open source design and Pondicherry Institute of Medical Sciences (PIMS)

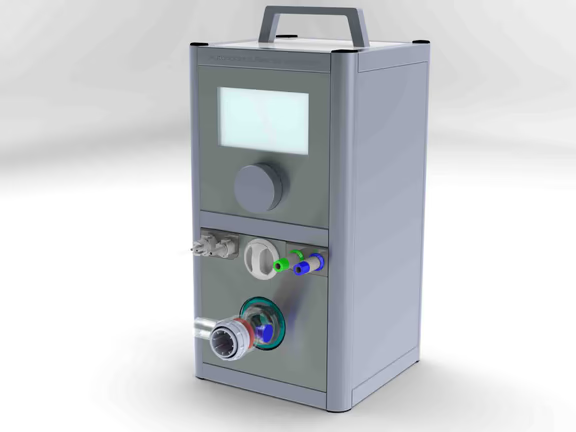

2 The JASAN ventilator

The JASAN initiative.

Five individuals came together, Jorge, Akash, Sukrit, Alex and Nigel (hence ‘Jasan’) with complementary skills motivated to help. Akash and Sukrit, who both grew up in Auroville, already had a history of collaborating on technological innovations in Auroville, such as electric bikes. They were joined by the other three team members – Jorge, Alex and Nigel – who are industrial designers or engineers.

Akash recalls being asked, “Why don’t you guys do something in Auroville like making cheap ventilators?” Akash’s first response was, “You must be joking”. But they started experimenting with different versions, testing and learning as they went along. Alex, the industrial designer, read up about ventilators and did the drawings. Sukrit “drilled a few holes” and tested the feasibility of the design by building some prototypes.

The team had to constantly adapt, due to the shortage of parts available under lockdown. “I had only one kilo of plastic for 3D printing so we had to think hard about what we wanted to print,” says Jorge. “We even had to print our own screws!” For other ventilator parts, team members looked in their waste baskets. The early prototypes were classic examples of Indian ‘jugaad’ (out-of-the-box innovation), and were made from a muesli bottle and a pump motor from Aquadyn.

The design has evolved since although all the models used an ‘ambu bag resuscitator’, which is used for patients in an ambulance. In the latest design, a unique scissor design allows for very precise control of volume and pressure, and an LCD screen shows volume and pressure curves, FiO2 levels as well as blood oxygen saturation. This version is now “quite robust and ready for medical testing,” according to the team.

While the Jasan ventilator is much simpler than ones currently available (which have a turbine or compressed air source), it is the result of a collaboration with Pondicherry Institute of Medical Sciences (PIMS) hospital’s Dr Karnam Hasan. Dr Hasan told the team that a cheaper, simpler machine was beneficial for small clinics in rural areas. So the team responded by creating a machine that can also be used in hospitals when all other ventilators are in use. “It’s like you can drive a Mercedes or Suzuki – both have air-conditioning but with different features,” says Alex.

The team’s priority now is to finalise the product and get it medically certified. Of the five prototypes they are making, one will go to PIMS for testing, whilst two will be sent to Bangalore for certification. Once tested and certified, the ventilators will be manufactured on a greater scale through a partnership with an outside company. The partnership aims to ensure that the ventilators can be produced on a larger scale as quickly as possible, in order to help as many people. The JASAN team will license the design to the company through an Auroville unit, so that the royalties will benefit Auroville.

Jasan’s enterprise reflects the spirit of Auroville’s pioneers who learned on the job, as they built their vernacular windmills and houses. “Initially it had the Auroville spirit, we didn’t know where it was going,” recounts Akash. “The whole project came together in an Auroville way.” Jorge chimes in: “It was a collaboration, everybody worked with no interest other than to do something to improve the situation,” and Sukrit remembers that “In a time of crisis people come together; this happened too in the cyclone and tsunami.”

Tusky

The ventilator created by Aurovilian Samvit’s team is named ‘Tusky’, due to its elephantine appearance. Samvit, an industrial designer, wanted to make it as low-tech as possible so that it could be affordable and replicable. As he initially only had access to the existing materials in his workshop, the team engineered the project “to be adaptable to the materials available.”

Samvit points out that there are two types of ventilators: one runs at a pre-set speed, while the other adjusts to a patient’s breathing pattern and therefore needs to be adjustable with sensors.

Samvit decided not to work with airflow sensors becauseof their high price, and felt that something more affordable was needed immediately.

“I wanted to put ten ventilators in Santé to take care of Auroville. Each sensor costs 8-18,000 rupees and usually you need two for redundancy. I saw that this is not the kind of product we could pull off in a short time. Our ventilator is a basic system which can be taken home to your bedside and is low cost, easily recreated and intuitive to use. It is not meant to replace intra-tracheal pulmonary ventilation.”

Samvit’s machine pumps air through a column of water which creates positive end-expiratory pressure (PEEP) – the positive pressure that enables air to remain in airways at the end of a respiratory cycle. Adjustments can be made manually in this water pressure concept, and this design does away with components that may be difficult to source and can often be expensive. Measurements on the water tank connected to the machine provide readings to indicate the volume and pressure. The mechanical action of inflating and deflating the AMBU bag is provided by a windshield wiper motor, where the speed can be regulated.

He had a few breakthroughs in developing the latest model. “It’s typically not easy to measure the rotation of something. I looked at tachometers [an instrument which measures the working speed of an engine], but they were quite expensive and I didn’t think they would work well at low speeds. Then I remembered it is possible to measure the speed of a turntable using an app. After some searching, I have found an app that could be adapted to this machine to accurately measure breaths per minute. Something that would normally cost a lot of money was free and precise.”

Samvit has decided to make his invention available to the Open Source community. “It should remain within the Open Source community because I borrowed a lot of technologies, and they gave me a starting point. The first Open Source ventilator that I 3D printed and tried out, worked. We improved it, but I hope someone in the Open Source community will let us know of something even better.”

Currently Samvit does not foresee mass production, as it takes three days for his three person team to make one machine. His prototypes are being medically testedby the same PIMS medical team which is working with Jasan, and then he hopes to manufacture up to one hundred machines.

The creation process has been a fun challenge for Samvit. “It’s nice to solve big problems because usually my profession only solves inconveniences. But here something really important needed to be done, and that made it interesting”.

While the certification process will take at least until the end of the year, both teams are confident that their efforts to go into production will see fruition.

Dr Hasan from PIMS hospital has been the advisor for both of the Auroville teams. He points out that the innovative ventilators being developed by the two Auroville teams “will be of use beyond COVID-19 because India is in need of affordable and reliable models which can be deployed in more hospitals and made accessible for home use by long-term patients.”

For more information and updates go to: www.InspiredMachines.org